Unveiling the Excellence: Highlights of Korea’s Contract Manufacturing Organization (CMO) Facilities

Introduction:

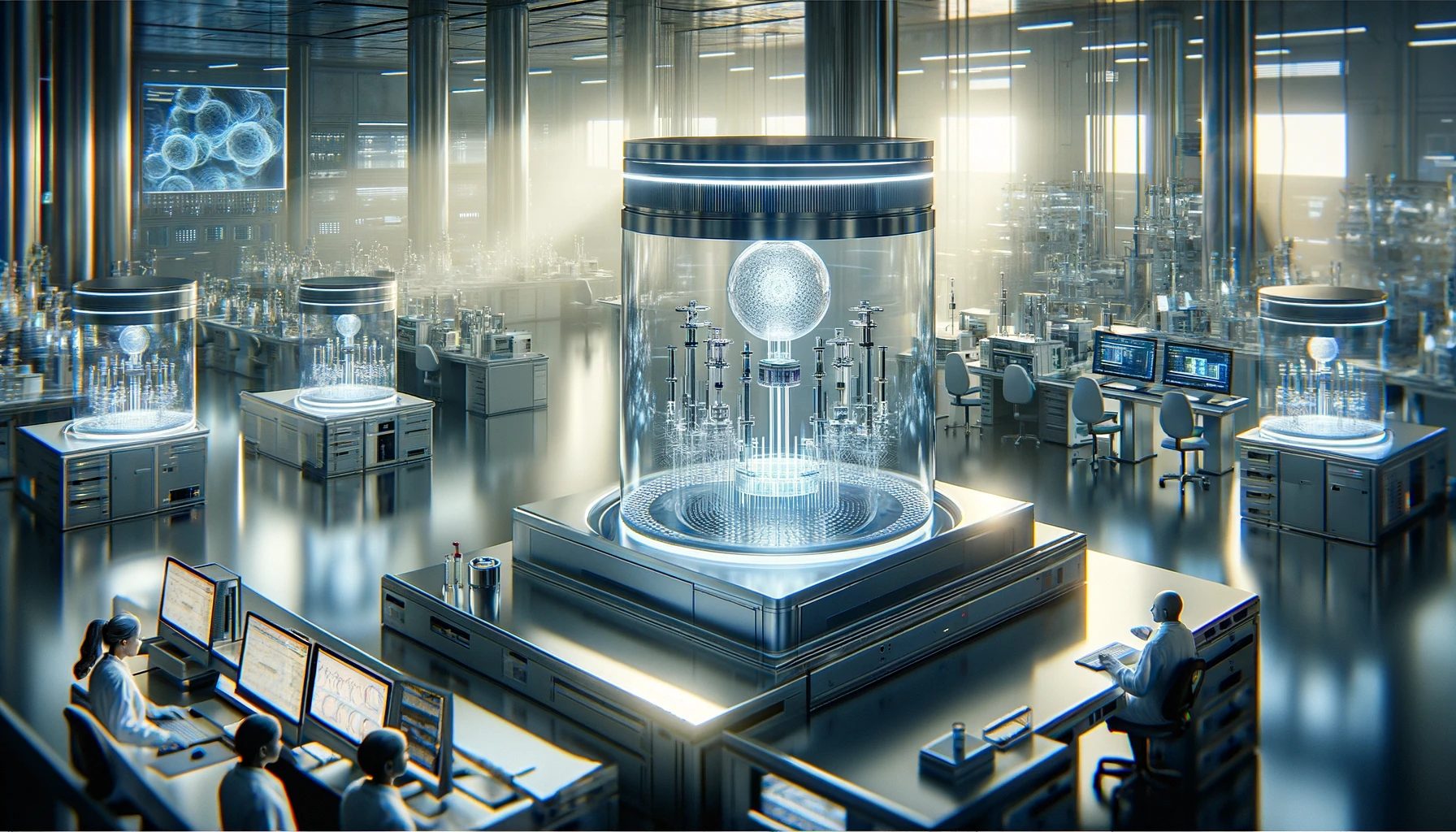

Advanced Manufacturing Technologies: Korea’s CMO facilities are equipped with advanced manufacturing technologies that enable the production of a wide range of pharmaceutical products, including small molecules, biologics, and biosimilars. These facilities boast state-of-the-art equipment, automated systems, and strict quality control measures to ensure the highest standards of manufacturing excellence. From formulation development and process optimization to scale-up and commercial production, Korea’s CMOs leverage innovative technologies to deliver high-quality products efficiently and cost-effectively.

Regulatory Compliance and Quality Assurance:

Korea’s CMO facilities adhere to stringent regulatory requirements, including Good Manufacturing Practices (GMP) and international quality standards. These facilities are regularly inspected by regulatory authorities to ensure compliance and maintain the integrity of the manufacturing processes. With a strong focus on quality assurance, Korea’s CMOs implement robust quality management systems, rigorous testing protocols, and comprehensive documentation practices, ensuring the safety, efficacy, and reliability of the products they manufacture

Flexibility and Customization

Korea’s CMO facilities offer a high degree of flexibility and customization to meet the diverse needs of their clients. Whether it’s adapting manufacturing processes to accommodate specific product requirements, providing tailored solutions for different dosage forms, or supporting clients in process optimization, Korea’s CMOs prioritize customer satisfaction and collaboration. This flexibility allows businesses to streamline their manufacturing operations, optimize resource utilization, and accelerate time-to-market for their products.

Cost Efficiency and Time-to-Market :

Outsourcing manufacturing to Korea’s CMO facilities can offer significant cost advantages for companies. The country’s competitive labor costs, efficient supply chain management, and government support programs create a favorable environment for cost-efficient manufacturing. Moreover, the expertise and experience of Korea’s CMOs help streamline production processes, reducing time-to-market for new products and enabling businesses to respond quickly to market demands.

Collaborative Partnerships and Value-added Services:

Korea’s CMO facilities foster collaborative partnerships with their clients, offering value-added services beyond manufacturing. These services include formulation development, analytical testing, regulatory support, and supply chain management, providing end-to-end solutions for the entire product lifecycle. By leveraging the expertise of Korea’s CMOs, companies can access comprehensive support and guidance, driving innovation, and enhancing their competitiveness in the global market.

Conclusion:

Korea’s Contract Manufacturing Organization (CMO) facilities stand at the forefront of the pharmaceutical and biotech manufacturing landscape, delivering excellence, regulatory compliance, and value-added services. To gain deeper insights into the highlights and capabilities of Korea’s CMO facilities, we invite you to download our comprehensive PDF guide: “Korea Contract Manufacturing Organization Facilities Highlights.” Discover the state-of-the-art technologies, regulatory compliance, and advantages that make Korea an exceptional destination for outsourcing manufacturing operations.